Customised Pneumatic Systems

60000 INR/Unit

Product Details:

- Model No As per project

- Cooling System Air Cooled (if required for specific components)

- Noise Level < 70 dB(A) under normal operation

- Drive Pneumatic Driven

- Frequency 50/60 Hz (if electric control panel is included)

- Motor Power Not ApplicablePneumatic System

- Power Rating Depends on pneumatic systems actuator and valves

- Click to View more

X

Customised Pneumatic Systems Price And Quantity

- 1 Unit

- 60000 INR/Unit

- User Manual, Test Report, Circuit Diagram Provided

- CE, ISO, ROHS available on request

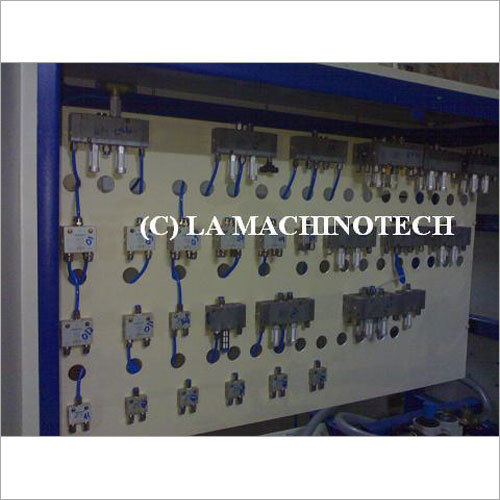

- Solenoid Valves, Manual Valves, Flow Control Valves

- Filtered, Dry Air (ISO 8573-1:2010 Class 2.4.2 or better recommended)

- Wall, Floor, Table-top, Customized Mountings

- IP54/IP65 Rated Control Panel (if equipped)

- Rotary, Linear, Grippers, Specialized Actuators available

- Double Acting, Single Acting, Guided Cylinders as per design

- Optimized as per duty cycle and actuator size

- Installation & AMC Available

- Integrated as per application

- Touchscreen HMI/LED indicators (Optional)

Customised Pneumatic Systems Product Specifications

- Manual, Semi-Automatic, Fully Automatic (as customised)

- Up to 10 Bar (customizable as per requirements)

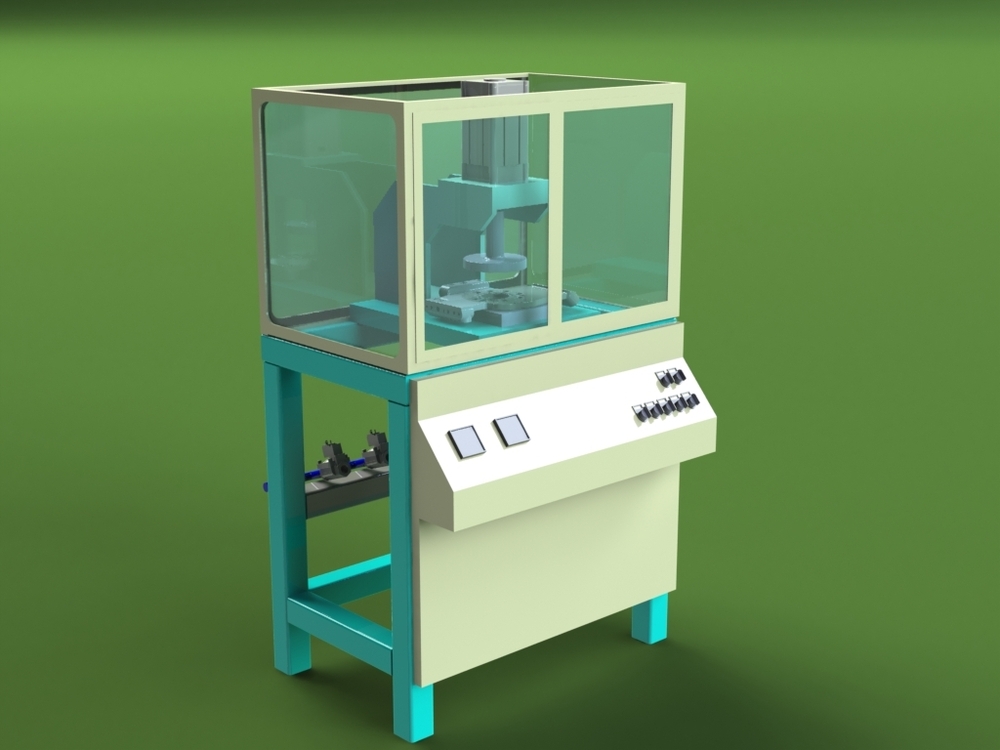

- Customised Pneumatic Systems

- < 70 dB(A) under normal operation

- As per project

- Customizable as per system design

- Air Cooled (if required for specific components)

- Compressed Air

- Not ApplicablePneumatic System

- Depends on pneumatic systems actuator and valves

- Standard Grey, Blue, or As per client requirement

- 50/60 Hz (if electric control panel is included)

- Pneumatic Driven

- Powder Coated/Epoxy Painted/Anodized

- Varies as per design

- Varies based on application requirement

- As per system configuration

- Industrial Automation, Material Handling, Packaging, Assembly Lines

- Customised Pneumatic Solution

- +/- 1 mm (application dependent)

- 5C to 50C

- PLC, Relay-based, or manual control options

- Not Applicable (Pneumatically Operated), Electric panel if provided: 220-240V AC

- Integrated Safety Components, Modular Design, Compact, Easily Expandable

- Digital/Analog Control, PLC Communication, Optional IoT integration

- Optional Inline Lubricators/Automatic

- Pneumatic Automation

- Heavy Duty/Modular Aluminium/Steel Frame

- User Manual, Test Report, Circuit Diagram Provided

- CE, ISO, ROHS available on request

- Solenoid Valves, Manual Valves, Flow Control Valves

- Filtered, Dry Air (ISO 8573-1:2010 Class 2.4.2 or better recommended)

- Wall, Floor, Table-top, Customized Mountings

- IP54/IP65 Rated Control Panel (if equipped)

- Rotary, Linear, Grippers, Specialized Actuators available

- Double Acting, Single Acting, Guided Cylinders as per design

- Optimized as per duty cycle and actuator size

- Installation & AMC Available

- Integrated as per application

- Touchscreen HMI/LED indicators (Optional)

Customised Pneumatic Systems Trade Information

- All India

Product Description

For a limited time, procure our top-rated Customised Pneumatic Systems, famed for delivering transcendent automation across diverse industrial sectors. Select from pivotal cylinder types, including double acting, single acting, and guided options tailored by design. Integrate high-performance solenoid, manual, or flow control valves, paired with rotary, linear, gripper, or specialized actuators. Each solution offers robust mounting options and optimized air consumption. Meeting stringent CE, ISO, and ROHS standards, our modular systems include safety interlocks, IP65-rated panels, and touchscreen interfaces, supported by installation and AMC. Secure your advanced system today!

Versatile Applications & Seamless Usage Directions

Customised Pneumatic Systems excel in a multitude of applications beyond conventional boundaries, driving automation in packaging, assembly lines, material handling, and more. Their pivotal roles flourish in factories, warehouses, and bespoke machine setups. Users are provided with comprehensive directions for commissioning and operating each tailored solution, ensuring optimal safety and performance. Our solutions adapt to complex layouts while prioritizing user-friendliness and efficiency, placing advanced technology within reach at various application sites.

Supply Ability, Market Reach & Premium Packaging

Our supply capability is configured to meet project-specific demands, ensuring seamless packing & dispatch of each system from India's pivotal industrial hubs. We principally serve the main domestic market, with flexible packaging that ensures your solution's safety during transit. Each order is accompanied by transparent list price documentation. Every system is carefully packed in premium-grade materials, guaranteeing damage-free delivery and maintaining strict standards throughout dispatch and delivery cycles.

Versatile Applications & Seamless Usage Directions

Customised Pneumatic Systems excel in a multitude of applications beyond conventional boundaries, driving automation in packaging, assembly lines, material handling, and more. Their pivotal roles flourish in factories, warehouses, and bespoke machine setups. Users are provided with comprehensive directions for commissioning and operating each tailored solution, ensuring optimal safety and performance. Our solutions adapt to complex layouts while prioritizing user-friendliness and efficiency, placing advanced technology within reach at various application sites.

Supply Ability, Market Reach & Premium Packaging

Our supply capability is configured to meet project-specific demands, ensuring seamless packing & dispatch of each system from India's pivotal industrial hubs. We principally serve the main domestic market, with flexible packaging that ensures your solution's safety during transit. Each order is accompanied by transparent list price documentation. Every system is carefully packed in premium-grade materials, guaranteeing damage-free delivery and maintaining strict standards throughout dispatch and delivery cycles.

FAQ's of Customised Pneumatic Systems:

Q: How do I determine which customised pneumatic system is ideal for my application?

A: Consult with our engineering team, who will assess your specific requirements-such as actuator type, valve configuration, mounting, and air quality-to recommend the most effective system for your intended use.Q: What benefits do your pneumatic systems offer over standard off-the-shelf solutions?

A: Our systems provide tailored automation with modular designs, expanded control options, and optimized air consumption-ensuring precise performance, efficiency, and integration within your unique operational environment.Q: Where can customised pneumatic systems be installed?

A: They can be installed across varied environments: from industrial assembly lines to material handling setups, packaging units, and custom machinery-supporting wall, floor, or table-top mounting as per your space and design needs.Q: What is the process for ordering and installing a pneumatic system?

A: Begin with a consultation, followed by design selection and customization. Upon confirmation, your system will be manufactured, subjected to rigorous testing, and delivered. Our team provides installation and after-sales maintenance as per your requirements.Q: When is it recommended to schedule servicing or AMC for pneumatic systems?

A: Preventive maintenance or AMC (Annual Maintenance Contract) scheduling depends on usage intensity and environment but is usually suggested every 6-12 months for optimal performance and safety.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS